Shaping the Future of Sustainable Hot Water Heating

The Mitsubishi Electric CAHV is a high-performance, eco-friendly heat pump water heater engineered as an alternative to fossil fuel systems with a low-carbon and energy-efficient solution.

The CAHV uses the low-GWP (148) R-454C refrigerant, setting a new standard in HVAC innovation. Offering an eco-friendly, future-proof solution, the CAHV delivers exceptional efficiency and reliable performance for new and retrofit applications in all climate conditions.

136,40 Btuh

Outdoor Temperature

Inverter

Technology

Provides Flexible Solutions

Features

Optimal Energy Performance

Achieves 2.85 COP. High heating output even in low ambient temperatures.

All-Weather Control

Outdoor operating range from -25 °C to 43 °C.

Leaving water temperatures up to 74 °C.

Streamlined Installation and Maintenance

Monobloc design simplifies setup. No field refrigerant piping required.

Design Flexibility

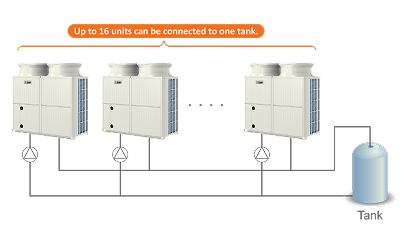

Multi-Unit Ready: Operates up to 16 units connected with one controller. No additional plant manager controls are required.

Onboard Controls: The CAHV is M-Net compatible.

Integrated or Standalone: City Multi CAHV and City Multi VRF units can be integrated into same Mitsubishi Electric central controller.

Various Configurations: The CAHV offers external outputs for backup heaters, analog capacity control input, defrost control, and more, ensuring the system can be easily adapted to meet various application requirements. The system capacity can easily be staged to accommodate large or growing loads.

Multi-Use Applications: The modular installation of the 40KW/136,480 Btuh Unit provides flexible solutions for multi-unit residences, hospitality, institutional buildings, recreation centres, and industrial facilities. Including space heating, sanitization, laundry services, sanitary water, pool heating, high heat-retention loads, and more.

Advanced Technology

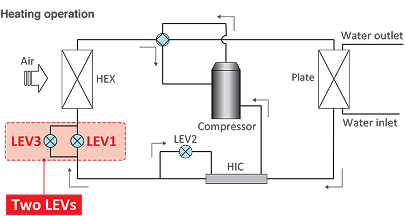

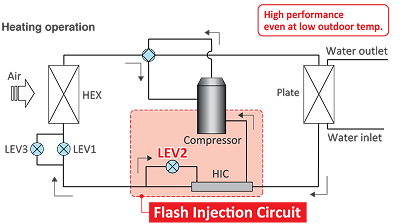

Refrigerant Circulation and Pressure Control with Two Linear Expansion Valves (LEVs)

R-454C refrigerant operates at a lower operating pressure than the commonly used high-GWP refrigerants found in many older HVAC systems.

Lower-density refrigerants can create challenges in maintaining circulation volume, particularly when the refrigerant circuit operating pressure drops in unfavourable conditions, such as low outdoor temperatures.

Mitsubishi Electric has solved the challenge using leading-edge Mitsubishi Electric inverter-driven scroll compressor technology that maximizes discharge volume and uses two parallel linear expansion valves (LEVs) to supply liquid refrigerant to the outdoor heat exchanger. This design optimizes the unit for flexible and variable capacity operation—even in low ambient temperatures.

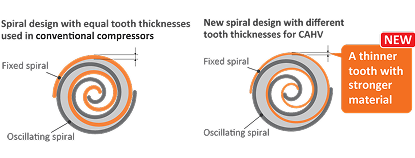

Next-Generation Compressor Technology

New Spiral Structure: R-454C benefits from a greater discharge volume to maximize efficiency. The optimized new compressor features a redesigned fixed spiral using new material, achieving thinner, stronger teeth (scroll flanks) with lengthened height. This innovation increases extrusion volume by 15% compared to a typical scroll compressor of a similar volumetric design.

Flash Injection Circuit

Mitsubishi Electric’s flash injection circuit delivers high performance in cold climates, meeting target leaving water temperatures even in challenging low ambient conditions.

The LEVs modulate the supply of liquid/gas two-phase refrigerant to the Heat Interchange Circuit (HIC), which improves the efficiency and capacity of the system by increasing system subcooling and improving mass flow rate and cooling of the compressor windings.

Inverter Frequency Control

The new inverter-driven compressor operates with modulating capacity. This allows the matching of hot water output to system demand (or load) at lower capacities, significantly reducing on/off cycling during low-load conditions – such as in shoulder seasons – and improving energy efficiency.

Discover the CAHV's Full Potential

Download the complete catalogue for detailed features and specifications.